Free shipping on domestic orders $65+

Why Cast Acrylic?

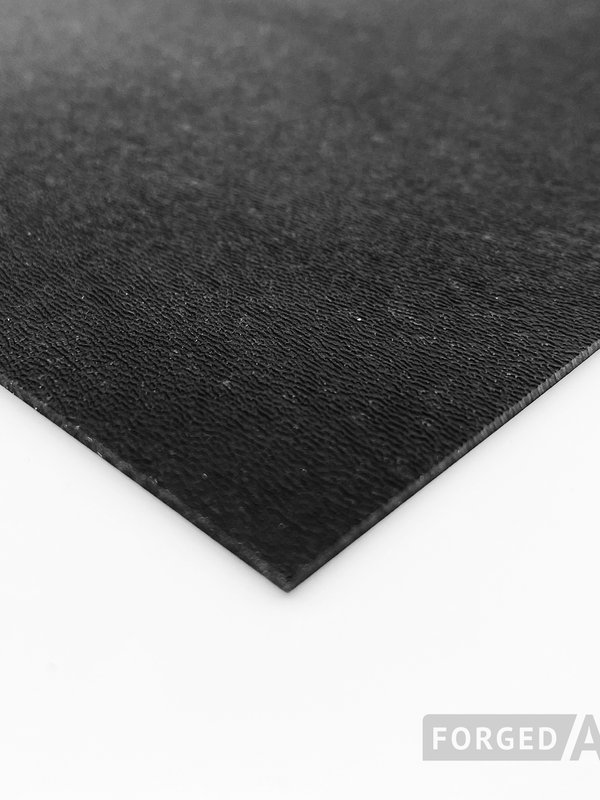

Cast Acrylic, commonly referred to as Plexiglass, is perfect for laser cutting! The small precut sizing makes it flexible and easy to use for those with smaller desktop lasers like the Glowforge, Dremel, or FSL Muse. Cast acrylic is a versatile plastic that will cut, drill and rout cleaner than extruded acrylic.

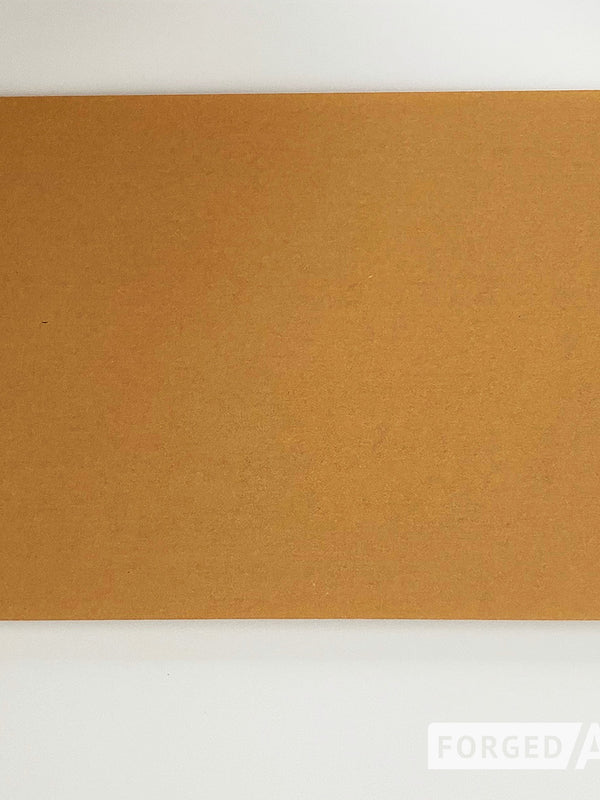

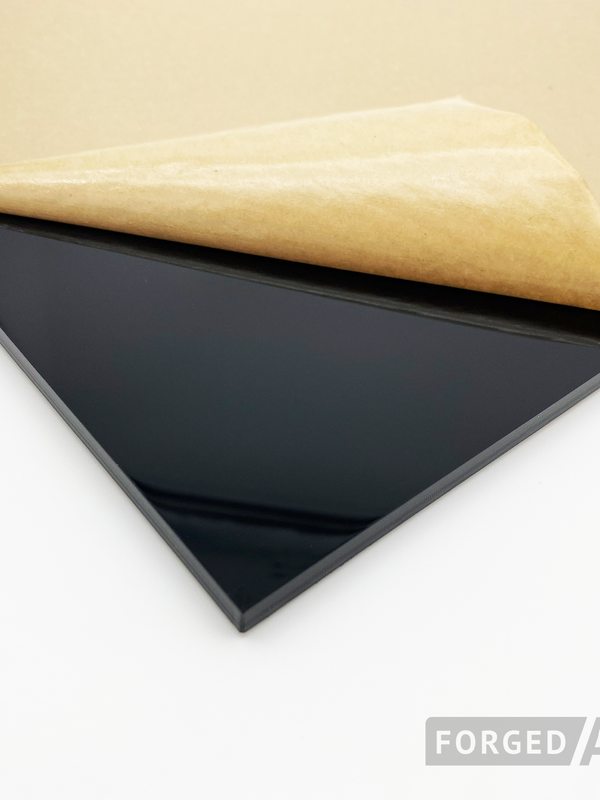

Cast acrylic sheets come covered with paper masking on both sides to protect the plastic from scuffs or scratches during cutting or transit.

How is Cast Acrylic Different from Extruded Acrylic?

Cast acrylic has a higher molecular weight, therefore it will cut, drill and rout cleaner. When machining cast acrylic, shavings will flake off whereas extruded acrylic shavings may gum up on the tool. Cast acrylic also offers better glue-joint effectiveness and performs better in laser cutting.

Continuous Service Temp: 180° F (Cast) vs. 160° F (Extruded)

Formability Temp: 340° F to 380° F (Cast) vs 290° F to 320° F (Extruded)

Sizing

Sheets use nominal sizing, please allow +(-) 1/8" for size to account for the ⅛” saw cutting kerf. Actual thickness is 0.118", all acrylic has a thickness tolerance. Actual thickness is typically between 0.115" - 0.136".

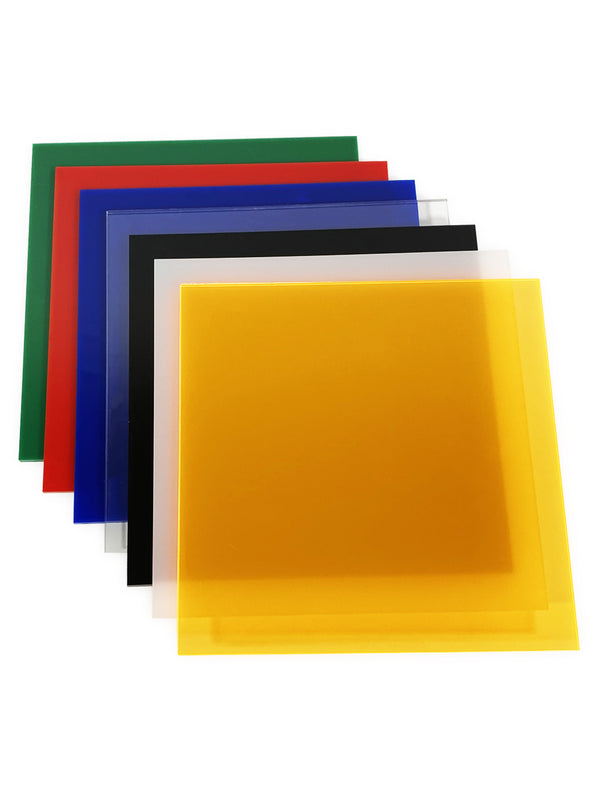

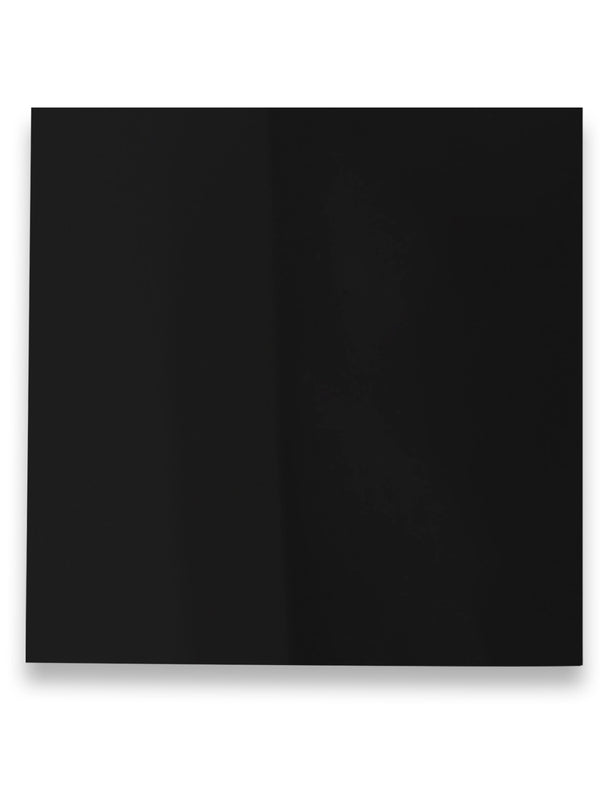

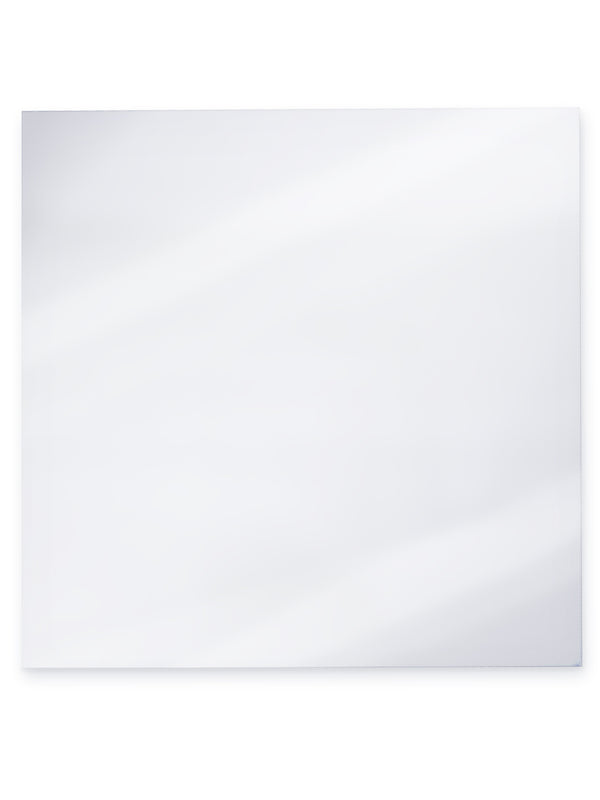

Transparency Guide

Translucent = Light & Shadows can be seen through Sheet.

Transparent = Images can be viewed through sheet (like tinted glass)

Opaque = Neither light nor images can be seen through the sheet

More Like This

Address:

801 Davis St. Ste C, Vacaville, CA 95687 USA

Location is not open to the public.

Email:

info@forgedacrylics.com

Product

Forged Acrylics

Latest News

Copyright © Forged Acrylics - All Right Reserved.