Free shipping on domestic orders $65+

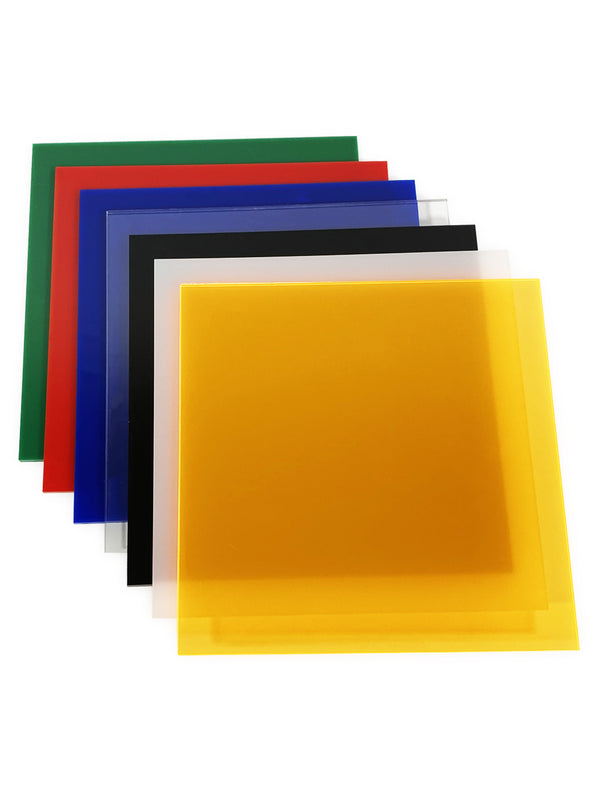

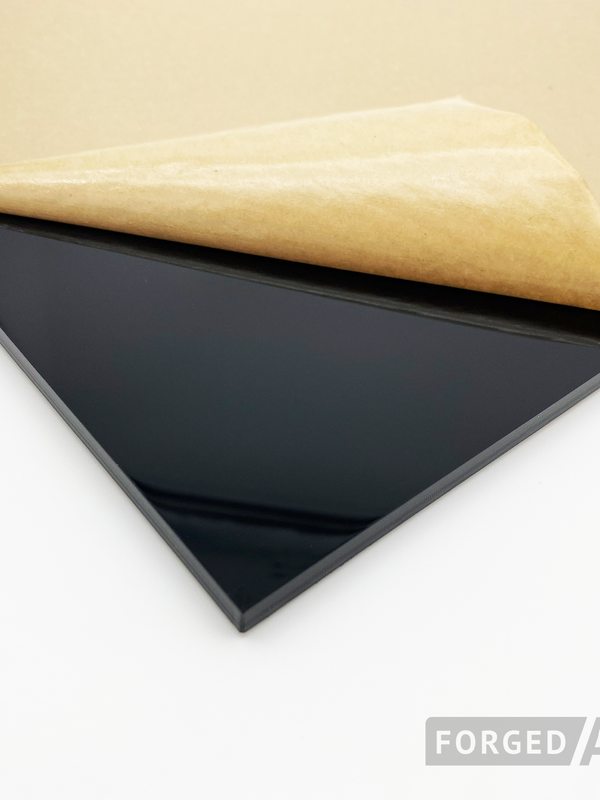

These are premium KYDEX T (as opposed to V) thermoform molding sheets, precut in 12x12". KYDEX is the industry leader in thermoform molding sheet material for DIY holster and sheath making. KYDEX sheets have excellent forming properties, which results in uniform wall thicknesses and crisp detail.

KYDEX thermoplastic is durable, scratch-resistant and requires low maintenance. The material doesn’t shrink, lose its color, or lose shape. Once you’ve completed the molding process, KYDEX holds it form extremely well. It can be hand-wiped clean, and is even waterproof. Unlike many other thermoforming sheets, KYDEX sheet has unusually high resistance to hot tearing.

KYDEX is a top-quality product that is made in the USA.

Forming Guidelines

- Oven temperatures should be set differently than the settings used for ABS or FR-ABS.

- Typical heater settings (percentage timers) are 30% – 50% top heaters and 50% - 70% bottom heaters.

- The most frequent problem is trying to heat the sheet too quickly, particularly on the primary surface.

- Cycle times will vary depending on the oven conditions and grade of KYDEX sheet being formed.

- When forming KYDEX sheet, it is better to rely on the sheet appearance during heating than on fixed cycle times.

- Forming temperatures – Guidelines: (Sheet should not exceed 204°C (400°F).

Temperatures

165 - 177°C (330 - 350°F) for < 1.50mm (0.060").182 - 196°C (360 - 385°F) for 1.50mm to 3.20mm (0.060" to 0.125").

196 - 204°C (385 - 400°F) for > 3.20mm (0.125")

Ideally the core sheet temperature should be within 10°F of the surface temperature.

Sheet Appearance During Heating

- The heating is marked by wide undulations and softening.

- The material will start to form small ripples (known as oil canning). .

- The material will start to smooth out and sag (KYDEX sheet will generally sag less than other thermoplastics due to its high melt strength. .

- The ripples will have smoothed out indicating that most stresses have been removed. 10 to 30 seconds afterwards the sheet is ready to form.

More Like This

Address:

801 Davis St. Ste C, Vacaville, CA 95687 USA

Location is not open to the public.

Email:

info@forgedacrylics.com

Product

Forged Acrylics

Latest News

Copyright © Forged Acrylics - All Right Reserved.