Key Highlights

- Thermoplastic molding techniques are commonly used in manufacturing due to their versatility and cost-effectiveness.

- Injection molding is the most popular thermoplastic technique for creating high-quality plastic products.

- Thermoplastic materials such as ABS, polypropylene, and polycarbonate offer various properties and applications.

- Advanced technologies like 3D printing and automation have revolutionized thermoplastic molding processes.

- Quality control is essential in thermoplastic molding to produce durable and reliable products.

- Sustainability is a key consideration in thermoplastic molding, focusing on recycling and reducing waste.

Introduction

Thermoplastic molding techniques have become a cornerstone in the manufacturing industry, providing a cost-effective and efficient way to produce high-quality plastic products. This guide aims to provide a comprehensive overview of thermoplastic molding techniques, including the various processes involved, the materials used, and the advancements in technology that have revolutionized this field. We will also discuss the benefits of thermoset injection molding, a process gaining popularity in recent years.

Thermoplastic materials, which can be melted and solidified repeatedly without undergoing a chemical change, are the primary materials used in thermoplastic molding. The injection molding process, in particular, has gained popularity due to its ability to produce complex and precise plastic parts at high volumes, making it the preferred choice in various industries. Other molding techniques such as blow molding, extrusion molding, hot mold molding, and rotational molding also play significant roles in the manufacturing industry, using cold material in thermoset injection molding and molten material in thermoplastic injection molding. Here, we explore some of the most commonly used materials in thermoplastic injection molding, their inherent properties, and typical applications.

In this guide, we will delve into the basics of thermoplastic molding, including the properties of thermoplastic polymers, the evolution of thermoplastic molding in manufacturing, and the key processes involved. We will also explore the different materials used in thermoplastic molding, their properties, and how to select the right material for specific projects. Additionally, we will discuss advanced thermoplastic molding technologies, such as 3D printing and automation, and their implications in the industry.

Whether you are a manufacturer looking to optimize your production processes or an individual interested in learning more about thermoplastic molding, this guide will provide you with the essential knowledge to understand and utilize these techniques effectively.

Overview of Thermoplastic Molding Techniques

Thermoplastic molding techniques encompass a range of processes used to shape thermoplastic materials into desired forms. The manufacturing process involves heating thermoplastic materials until they become molten and injecting or shaping them into molds to cool and solidify. This process allows for creating a wide variety of plastic parts and products. The choice of plastic material is crucial in determining the properties and characteristics of the final product. Different molding techniques, such as injection molding, blow molding, extrusion molding, and rotational molding, offer unique advantages and applications.

Understanding the Basics of Thermoplastic Molding

To understand thermoplastic molding, it's essential to grasp the basics of thermoplastic polymers. Thermoplastic polymers are long-chain molecules that can be repeatedly melted and solidified without undergoing a chemical change. When heated to their melting point, these polymers become molten and can be easily shaped or molded. This molten plastic is then injected into a mold cavity, which cools and solidifies into the desired shape.

The melting point of a thermoplastic polymer is a critical factor in the molding process. It determines the temperature at which the polymer transitions from solid to molten. Different thermoplastic materials have varying melting points, which affect the molding process and the properties of the final product. Understanding the behavior of thermoplastic materials at different temperatures is essential for successful molding results.

The Evolution of Thermoplastic Molding in Manufacturing

Thermoplastic molding has evolved significantly in the manufacturing industry, revolutionizing production processes and opening up new possibilities. In the past, thermosetting plastics, which undergo a chemical change during molding, were prevalent. However, thermoplastic injection molding emerged as a game-changer due to its superior flexibility, efficiency, and cost-effectiveness.

The production process of thermoplastic injection molding involves injecting molten plastic into a mold cavity under high pressure. This process, also known as the thermoplastic injection molding process, offers numerous advantages, including high production volumes, complex part geometries, and the ability to create products with tight tolerances and excellent surface finishes. Additionally, developers get to use the thermoplastic injection molding process for many applications, as it can produce anything from cell phone cases to car door panels with good accuracy and surface finish. This evolution of thermoplastic molding has dramatically impacted the manufacturing industry and is vital for creating a wide range of products.

Fundamental Processes in Thermoplastic Molding

Thermoplastic molding encompasses several key processes commonly used in the manufacturing industry. The primary process is plastic injection molding, which involves injecting molten plastic into a mold cavity using a thermoplastic injection molding machine. Other vital processes include blow molding, which is used to create hollow plastic parts, and extrusion molding, which involves pushing molten plastic through a die to create continuous shapes such as tubes or sheets. Vacuum cleaners, kettles, toasters, toys, machine screws, gear wheels, and power tool casings are just a few examples of products made using thermoplastic injection molding. Each of these processes has its own unique advantages and applications, making them valuable techniques in the thermoplastic molding industry.

Injection Molding: A Deep Dive

Due to its versatility and efficiency, injection molding is the most widely used thermoplastic molding process. Here are some critical aspects of injection molding:

- The process starts with the injection unit, which feeds the thermoplastic material into the heated barrel.

- The material is then pushed through the barrel by a reciprocating screw, where it melts and becomes molten plastic.

- The molten plastic is injected into the mold cavity under high pressure, filling the mold.

- Injection and holding pressure are applied to ensure the mold cavities are correctly filled and minimize defects.

- The mold is cooled, and the molded part is ejected and ready for further processing or use.

Injection molding offers numerous advantages, including high production rates, cost-effectiveness, and the ability to create complex and precise parts with tight tolerances.

Extrusion Molding: Process and Applications

Extrusion molding is a thermoplastic process that involves pushing molten plastic through a die to create continuous shapes. Here are some critical points about extrusion molding:

- The process begins with heating the thermoplastic material to a high temperature until it becomes molten.

- The molten plastic is then forced through a die, which shapes it into a continuous form, such as a tube or sheet.

- Extrusion molding is commonly used to produce automotive parts, pipes, profiles, and packaging materials.

- It is particularly suitable for manufacturing products with a uniform cross-section and long lengths.

- Various thermoplastic materials can be used in extrusion molding, offering various properties and applications.

Blow Molding: Techniques and Uses

Blow molding is a thermoplastic molding technique used to create hollow plastic parts. Here are some key aspects of blow molding:

- The process involves melting the thermoplastic material and injecting it into a mold cavity.

- High pressure is applied to the molten plastic, causing it to expand and conform to the shape of the mold.

- The mold is then cooled, and the plastic solidifies, resulting in a hollow part with a desired shape.

- Blow molding is commonly used to produce bottles, containers, and other consumer products.

- It offers advantages such as high production rates, excellent surface finish, and the ability to create complex shapes.

Rotational Molding: Exploring its Unique Advantages

Rotational molding, or roto-molding, is a thermoplastic technique with unique advantages. Here are some key points about rotational molding:

- The process involves heating a mold and rotating it in multiple axes simultaneously.

- The thermoplastic material is then added to the mold, which coats the interior surface as the mold rotates.

- The mold is cooled, and the plastic solidifies, resulting in a hollow part with uniform thickness and excellent impact strength.

- Rotational molding is particularly suitable for producing large, hollow parts with complex shapes.

- It offers advantages such as low production costs, design flexibility, and the ability to use a variety of thermoplastic materials.

Materials Used in Thermoplastic Molding

Thermoplastic molding techniques utilize a wide range of materials, each with its own unique properties and applications. Some commonly used thermoplastic materials include:

- Acrylonitrile Butadiene Styrene (ABS): Known for its high impact strength, scratch resistance, and durability. It is widely used in the automotive industry for manufacturing radiator grilles, instrument panels, and other components.

- Polypropylene (PP): Preferred for its high flexibility, lightness, and chemical resistance. It is commonly used in the manufacturing and packaging products such as washing machine drums and automotive parts.

- Acrylic (PMMA): Offers hardness comparable to aluminum and is commonly used for lenses, control panels, and other optical applications.

These materials and others, like polyethylene and polystyrene, provide a wide range of properties and functionalities in thermoplastic molding.

Properties of Common Thermoplastic Materials

Different thermoplastic materials offer various properties that make them suitable for specific applications. Here are some key properties of common thermoplastic materials:

- Impact resistance: Certain thermoplastic materials, such as ABS, have excellent impact resistance, making them suitable for applications that require durability and toughness.

- Heat resistance: Thermoplastic materials like polycarbonate and polypropylene exhibit high heat resistance, allowing them to withstand elevated temperatures without deformation or degradation.

- Moisture absorption: Some thermoplastic materials, such as nylon, have a higher tendency to absorb moisture, which can affect their properties and performance in specific applications.

Understanding the properties of different thermoplastic materials is essential in selecting suitable materials for specific projects to ensure optimal performance and longevity.

Selecting the Right Material for Your Project

Choosing the right material for a thermoplastic molding project is crucial for achieving the desired results. Several factors should be considered when selecting the material:

- Desired shape and functionality: Different materials have unique properties that suit specific shapes, sizes, and functionalities.

- Tensile strength: Depending on the application, the material's tensile strength should be evaluated to ensure it can withstand the required loads and stresses.

- Environmental factors: Consider the material's resistance to chemicals, temperature variations, and exposure to UV radiation or moisture.

By carefully evaluating these factors and consulting with experts, you can select the right material for your project, ensuring optimal performance and longevity of the final product.

Advanced Thermoplastic Molding Technologies

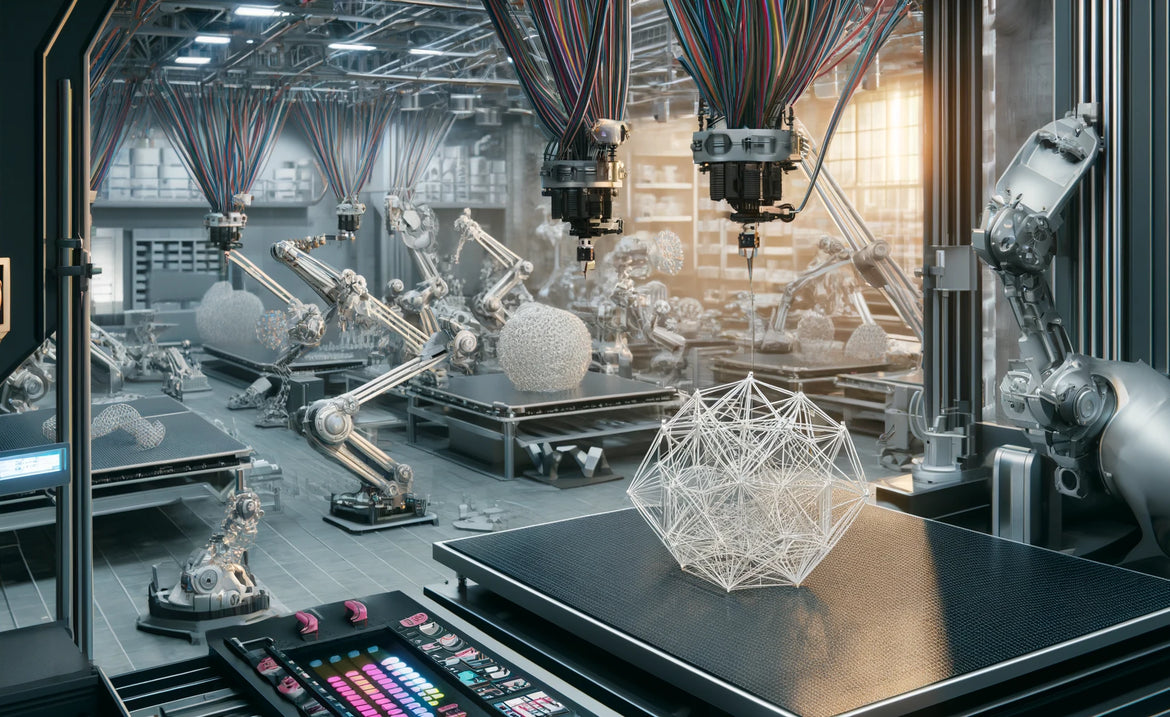

Advancements in technology have revolutionized thermoplastic molding, offering new possibilities and improved efficiencies. Some advanced thermoplastic molding technologies include:

- 3D printing: Enables the rapid prototyping of complex geometries and the production of custom parts with minimal waste.

- Automation: Incorporating robotic systems and advanced machinery streamlines molding, reducing human error and increasing productivity.

- Innovative molding techniques: Constant research and development in thermoplastic molding have led to the discovery of new techniques that offer improved efficiency, cost-effectiveness, and quality.

These advancements have expanded the capabilities of thermoplastic molding, making it a versatile and dynamic field within the manufacturing industry.

3D Printing with Thermoplastics: Innovations and Implications

3D printing has revolutionized the world of thermoplastic molding, offering new possibilities and applications. Here are some critical aspects of 3D printing with thermoplastics:

- Rapid prototyping: 3D printing allows for the quick production of prototypes, enabling designers to test and refine their designs before moving to mass production.

- Complex geometries: With 3D printing, intricate and complex shapes can be easily produced, eliminating the need for multiple manufacturing processes.

- Custom parts: 3D printing enables the production of customized parts with minimal setup and tooling costs, making it ideal for low-volume or one-off manufacturing.

The implications of 3D printing with thermoplastics are vast, allowing for greater design freedom, reduced waste, and increased customization in the manufacturing industry.

Automation in Thermoplastic Molding: Trends and Future Outlook

Automation plays a significant role in thermoplastic molding, offering several benefits regarding production efficiency and cost savings. Automated systems have revolutionized molding by increasing productivity and reducing labor costs. These systems can perform material handling, mold changes, and quality inspections with high precision and speed. Manufacturers can achieve consistent and high-quality results by automating repetitive and complex processes. Additionally, automation allows for real-time monitoring and data collection, enabling better quality control and optimization of the production process. As technology advances, we can expect even more sophisticated automated systems, further enhancing the efficiency and effectiveness of thermoplastic molding processes.

Design Considerations for Thermoplastic Molding

When it comes to thermoplastic molding, proper design considerations are essential for achieving optimal results. Mold design plays a crucial role in determining the outcome of the molded part. Factors such as the number of mold cavities, gate design, and cooling system design can significantly impact the quality and efficiency of the molding process. Additionally, the runner system, which includes the sprue, runners, and gates, must be carefully designed to ensure proper flow of the molten plastic. The parting line, where the two halves of the mold meet, should also be considered to ensure easy mold release and avoid defects on the final part.

Importance of Mold Design in Thermoplastic Molding

Mold design is a critical factor in thermoplastic molding as it directly affects the quality and efficiency of the process. The mold's design determines the final product's shape, size, and features. A well-designed mold ensures proper molten plastic filling, minimizing the chances of defects like voids, sink marks, or warping. The mold cavities must be designed to allow for easy flow of the molten plastic and efficient cooling. The cooling time is crucial as it affects the cycle time and overall production efficiency. The mold design should also consider factors like the heated barrel temperature, injection pressure, and mold release mechanisms. Shot size, or the amount of plastic injected into the mold, is also an important consideration in mold design as it directly affects the weight and volume of the finished part. By paying attention to mold design and shot size, manufacturers can achieve high-quality and precise molded parts consistently, making it a crucial aspect of producing different parts in thermoplastic molding.

Overcoming Design Challenges in Thermoplastic Molding

Thermoplastic molding often involves challenges in designing complex parts or using high-strength materials. Complex designs require careful consideration of moldability and the implementation of advanced molding techniques like thin-wall molding or overmolding. High-strength materials may require modifications to the mold design to withstand the increased stress and temperature during the molding process. Design optimization techniques, such as the use of simulation software, can help identify potential issues and optimize the design for better manufacturability. By overcoming these design challenges, manufacturers can produce intricate and durable thermoplastic parts that meet the specific requirements of their outdoor applications.

Quality Control and Optimization in Thermoplastic Molding

Quality control and optimization are crucial elements in thermoplastic molding to ensure consistent and high-quality products. Quality control measures, such as inspection processes and testing, help identify and eliminate defects before the final products are delivered. By implementing optimization techniques, such as process parameter optimization or mold flow analysis, manufacturers can improve the efficiency and effectiveness of the production process. These techniques help optimize cycle times, reduce energy consumption, and minimize waste generation. Manufacturers can achieve cost-effective and sustainable thermoplastic molding processes by focusing on quality control and optimization.

Ensuring Product Quality through Effective Molding Practices

Ensuring product quality is a top priority in thermoplastic molding, and effective molding practices are crucial in achieving this goal. Quality assurance starts with thorough inspection processes at every stage of the production process, from material selection to mold design, molding, and post-processing. These inspections help identify any potential defects or inconsistencies early on and allow for timely corrections. Cycle times, which include the time required for filling, cooling, and ejection of the part, must be carefully managed to ensure consistent quality and efficient production. By implementing effective molding practices and maintaining strict quality control measures, manufacturers can deliver high-quality thermoplastic molded products to their customers.

Optimization Techniques for Thermoplastic Molding Processes

Process optimization is crucial in thermoplastic molding to improve efficiency, reduce energy consumption, and minimize waste. Several techniques can be employed to optimize the molding process, such as optimizing process parameters, using advanced mold designs, or implementing automation technologies. Process parameter optimization involves fine-tuning variables like melt temperature, injection speed, and packing pressure to achieve the desired part quality and reduce material waste. Advanced mold designs, including conformal cooling channels or hot runner systems, can help optimize cycle times and improve energy efficiency. Automation technologies, such as robotic part handling or real-time monitoring systems, can enhance process control and reduce human error. Manufacturers can achieve cost-effective and sustainable thermoplastic molding by utilizing these optimization techniques.

|

Column Name A |

Column Name B |

|

Process Parameter Optimization |

Fine-tuning variables like melt temperature, injection speed, and packing pressure to achieve desired part quality and reduce material waste |

|

Advanced Mold Designs |

Conformal cooling channels, hot runner systems to optimize cycle times and improve energy efficiency |

|

Automation Technologies |

Robotic part handling, real-time monitoring systems to enhance process control and reduce human error |

Environmental Impact and Sustainability in Thermoplastic Molding

Environmental impact and sustainability are critical aspects of thermoplastic molding. Manufacturers are increasingly adopting sustainable practices to minimize their environmental footprint. Recycling plays a vital role in reducing waste and conserving resources. Thermoplastic materials can be recycled and reused, reducing the reliance on virgin materials. Additionally, sustainable practices such as green manufacturing, use of eco-friendly materials, and lifecycle assessments are being implemented to reduce the overall environmental impact of thermoplastic molding processes. By embracing these sustainable practices, manufacturers can contribute to a greener and more sustainable future.

Recycling and Reuse of Thermoplastics

Recycling and reusing thermoplastics are critical strategies for minimizing waste and conserving resources in thermoplastic molding. Manufacturers are implementing recycling programs to collect and process plastic waste, enabling the recovery of valuable materials. The recycled plastics can be used as feedstock for new manufacturing processes through material recovery, reducing the need for virgin materials. This conserves resources and reduces energy consumption and greenhouse gas emissions associated with producing new plastics. Additionally, recycling and reuse of thermoplastics contribute to the circular economy, where resources are kept in use for as long as possible, maximizing their value and minimizing environmental impact. By embracing recycling and reuse initiatives, manufacturers can reap environmental benefits and contribute to a more sustainable future.

Sustainable Practices in Thermoplastic Molding

Sustainable practices in thermoplastic molding focus on minimizing the environmental impact throughout the entire lifecycle of the product. Green manufacturing techniques, such as energy-efficient processes, waste reduction, and renewable energy sources, are being adopted to minimize resource consumption and emissions. Additionally, using eco-friendly materials, such as biodegradable or bio-based plastics, reduces the reliance on fossil fuels and lowers the carbon footprint. Lifecycle assessment is another critical aspect of sustainable practices, where the environmental impacts of a product are evaluated throughout its entire life cycle, from raw material extraction to disposal or recycling. By implementing these sustainable practices, manufacturers can reduce their environmental footprint and contribute to a more sustainable future.

Conclusion

In conclusion, mastering the various thermoplastic molding techniques can significantly enhance your manufacturing processes. Understanding the fundamentals, materials, and advanced technologies in thermoplastic molding is crucial for achieving high-quality products. By focusing on design considerations, quality control, and sustainability practices, you can optimize your molding processes for efficiency and environmental responsibility. Embracing innovation and staying informed about the latest trends will keep you at the forefront of thermoplastic molding advancements. Whether it's injection molding, extrusion molding, or rotational molding, each technique offers unique benefits that can be leveraged to meet your project requirements effectively.

Frequently Asked Questions

What Are the Most Common Defects in Thermoplastic Molding and How to Avoid Them?

Some of the most common defects in thermoplastic molding include sink marks, warping, voids, burn marks, and weld lines. These defects can be avoided by optimizing process parameters, ensuring proper mold design, and implementing appropriate cooling techniques. Proper design considerations, material selection, and mold maintenance are crucial in preventing these defects.