Key Highlights

- Moldable plastic is a versatile and transparent solution for various applications.

- It can be molded into shape by using heat and tools.

- Plastic is strong, reusable, and can be modified as needed.

- It is an excellent alternative for crafts, art, cosplay, and home repair.

- The process of molding plastic at home is simple and safe.

- Heating techniques, molding tips, and finishing procedures are essential to achieve desired results.

Introduction

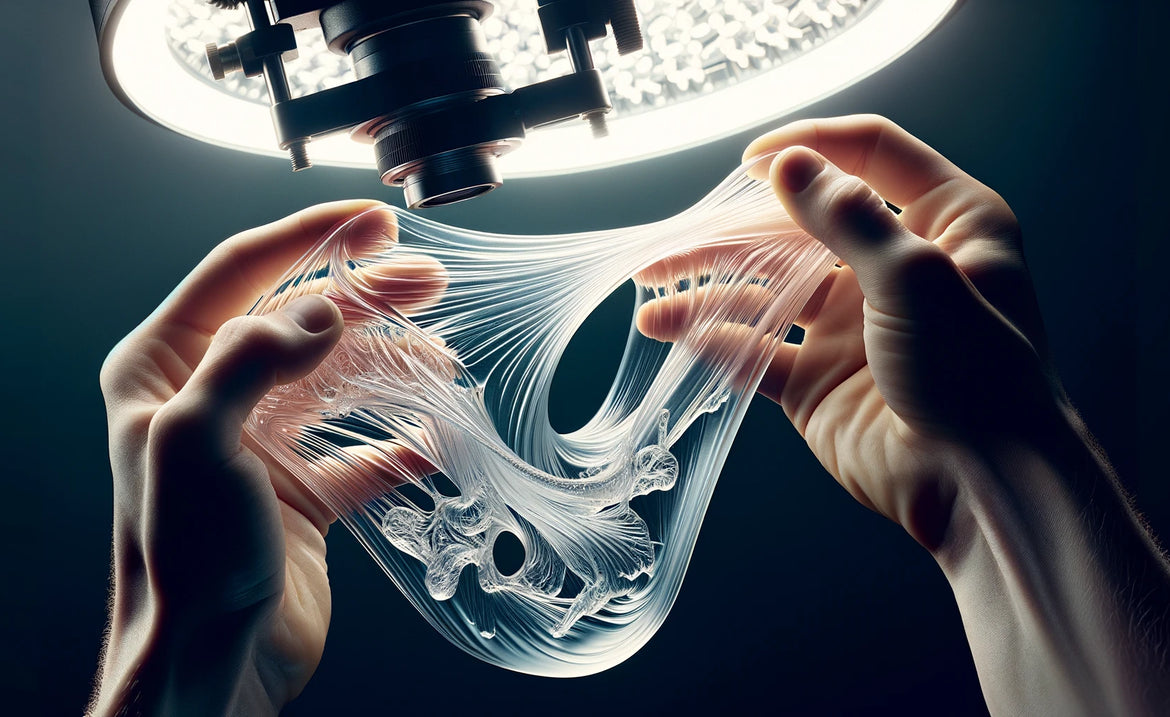

Moldable plastic is a unique and innovative material that provides endless possibilities for creativity and practicality. With its ability to be molded into any shape and its clear appearance, moldable plastic has become a popular choice for various applications. Whether you are a hobbyist, artist, cosplayer, or simply someone who enjoys DIY projects, moldable plastic offers a versatile solution to bring your ideas to life.

Understanding Moldable Plastic

Moldable plastic, also known as thermoplastic, is a type of plastic that becomes moldable when exposed to heat. It comprises small pellets or beads that can be melted and shaped into different forms. These pellets are usually made from a combination of polymers and other additives to give the plastic its desired properties. Moldable plastic can be easily manipulated by hand or with the help of tools to create intricate designs or functional objects.

Definition and Composition

Moldable plastic, also called thermoplastic, is a type of plastic that can be melted and shaped into various forms. It comprises small pellets or beads, typically made from polymers and additives. The composition of moldable plastic allows it to be heated and molded repeatedly without losing its properties. This versatility makes it popular among artists, craftsmen, and DIY enthusiasts. Moldable plastic can be easily colored using acrylic paints, alcohol inks, or other suitable coloring agents, allowing endless creative possibilities.

Types and Grades of Moldable Plastic

There are several types and grades of moldable plastic available in the market. Moldable pellets, known as thermoplastic beads, are commonly used for various crafts and projects. These pellets come in different sizes and melting points, allowing users to choose the most suitable option for their needs. Some popular types of moldable plastic include polycaprolactone (PCL) and polypropylene. Each type has unique properties and characteristics, making it suitable for different applications. The grade of moldable plastic also plays a role in determining its quality and performance. Higher-grade materials often offer better durability, strength, and flexibility.

Benefits of Using Moldable Plastic

Moldable plastic offers numerous benefits, making it an ideal choice for many projects. Its versatility allows it to be used in various applications, from arts and crafts to home repair and prototyping. The durability and strength of moldable plastic make it a reliable material that can withstand everyday use. Additionally, its clear and transparent appearance gives a professional finish to any project. Furthermore, moldable plastic is reusable, allowing users to modify and reshape their creations.

Versatility in Applications

Moldable plastic's versatility makes it an excellent choice for various applications. Here are a few examples:

- Crafts: Moldable plastic can create unique and intricate designs for jewelry, sculptures, and decorative items.

- Cosplay: It is a popular material for creating props, armor, and accessories among cosplayers.

- Home Repair: Moldable plastic can fix broken items, create custom brackets, or replace missing parts.

- Prototyping: It is an ideal material for rapid prototyping, allowing designers to bring their ideas to life quickly and cost-effectively.

Durability and Strength

One of the critical advantages of moldable plastic is its durability and strength. When properly molded and cooled, the plastic becomes solid and rigid, capable of withstanding everyday use. Polly Plastics, a trusted brand in the field, offers high-quality moldable plastic pellets that ensure durability and longevity. Once you have created your desired shape or object, you can trust that it will maintain its form and structural integrity. Whether you are creating a decorative piece or a functional item, moldable plastic provides the strength and durability needed to stand the test of time.

The Process of Molding Plastic at Home

Molding plastic at home is a simple and rewarding process that allows you to unleash your creativity. By following a few steps, you can transform moldable plastic pellets into any shape you desire. The process involves preparing your workspace, ensuring safety measures, and using heating techniques to melt the plastic. Once the plastic is malleable, you can mold and shape it according to your needs. Finally, cooling and finishing procedures are used to solidify the plastic and give it a polished look.

Preparing Your Workspace

Before you start molding plastic at home, it is essential to prepare your workspace to ensure safety and efficiency. Here are some critical steps to consider:

- Choose a well-ventilated area with a heat-resistant surface.

- Keep flammable materials and open flames away from your workspace.

- Use heat-resistant gloves to protect your hands from hot plastic.

- Ensure that you have all the necessary tools and materials within reach.

- Set the temperature to a safe and appropriate level, usually around 150°F.

These precautions will help create a safe and conducive environment for molding plastic at home.

Safety Measures to Consider

Molding plastic at home requires a certain level of caution to prevent accidents and ensure personal safety. Here are some essential safety measures to consider:

- Always supervise children when working with moldable plastic to prevent choking hazards.

- Use heat-resistant tools and gloves to protect yourself from burns.

- Avoid direct contact with hot plastic and use suitable utensils for handling.

- Never heat moldable plastic in a microwave, as it can cause uneven melting or damage to the appliance.

By following these safety measures, you can enjoy molding plastic while minimizing potential risks.

Step-by-Step Guide to Working with Moldable Plastic

Working with moldable plastic involves critical steps to achieve the desired results. By following a systematic process, you can easily mold, shape, and finish your creations. The steps include heating techniques and temperatures, molding and shaping tips and cooling and finishing procedures. Understanding and implementing these steps can bring your ideas to life and create unique and personalized objects.

Heating Techniques and Temperatures

Heating the moldable plastic is a crucial step in the molding process. Here are a few popular heating techniques and their corresponding temperatures:

- Hot Water: Place the moldable plastic pellets in a heat-resistant container and submerge them in hot water (above 150°F). Allow the pellets to melt until they turn transparent and malleable.

- Heat Gun: Use a heat gun to direct hot air onto the plastic pellets until they soften and become pliable.

- Oven: Preheat an oven to a low temperature (around 170°F) and place the plastic pellets on a heat-resistant surface. Monitor the pellets closely until they melt and can be molded.

Choosing the appropriate heating technique and maintaining the recommended temperatures can achieve the desired consistency for molding the plastic.

Molding and Shaping Tips

Molding and shaping the melted plastic require some techniques to achieve the desired results. Here are a few tips to keep in mind:

- Use your hands or tools to mold the plastic while it is still pliable.

- Apply gentle pressure to shape and form the plastic according to your design.

- If using tools, ensure they are clean and suitable for working with moldable plastic.

- Consider using a mold or template to achieve specific shapes or forms.

These tips will help you mold and shape the plastic effectively, allowing you to bring your creative vision to life.

Cooling and Finishing Procedures

Once the plastic has been molded and shaped to your satisfaction, it needs to cool and solidify. Cooling and finishing procedures are essential to ensure your creations' longevity and professional appearance. Here are a few essential steps:

- Allow the plastic to cool naturally at room temperature until it hardens completely.

- If desired, use cold water or a cooling agent to speed up the cooling process.

- Once cooled, sand the edges or surfaces for a smoother finish.

- Apply a varnish or sealant to protect the plastic and give it a polished look.

By following these cooling and finishing procedures, you can enhance your moldable plastic creations' durability and aesthetic appeal.

Creative Projects with Moldable Plastic

Moldable plastic opens up a world of creative opportunities. From DIY jewelry and accessories to custom tools and gadgets, there are numerous ways to unleash your creativity with this versatile material.

DIY Jewelry and Accessories

Creating your jewelry and accessories is a popular DIY trend, and moldable plastic provides the perfect medium to bring your ideas to life. Here are some ways you can use moldable plastic to create stunning pieces:

- Statement Necklaces: Moldable plastic can be molded into intricate shapes and designs, allowing you to create unique and eye-catching necklaces. Add a touch of color with alcohol inks for a vibrant and personalized look.

- Earrings: Moldable plastic is lightweight, making it ideal for creating earrings. Mold it into different shapes, such as geometric or floral patterns, and add your favorite color palette for a fun and stylish accessory.

- Hair Accessories: From hair clips to headbands, moldable plastic can be shaped into various hair accessories. Let your creativity flow and design pieces that perfectly complement your hairstyle.

- Bracelets: Create customized bracelets by molding the plastic into bangles or cuff designs. Experiment with different textures and finishes, such as embossed patterns or metallic effects, for a truly unique accessory.

Custom Tools and Gadgets

Moldable plastic is not limited to just decorative items; it can also be used to create custom tools and gadgets. Here are some examples:

- Custom Grips: Moldable plastic can be molded around the handles of tools, providing a comfortable grip tailored to your hand shape and size. This is especially useful for tools that require repetitive use or tools with handles that are not ergonomically designed.

- Prototypes: Moldable plastic is a popular choice for prototyping due to its easy moldability and reusability. Whether creating a new gadget, a small mechanism, or a custom part, moldable plastic lets you iterate and refine your design quickly.

- Brackets and Connectors: Moldable plastic can create custom brackets and connectors for various applications. Whether you need to secure two objects together or create a mounting solution, moldable plastic offers a flexible and versatile solution.

Conclusion

Moldable plastic provides endless opportunities for creativity and practicality. Understanding its composition, types, and benefits is key to unlocking its potential. From DIY projects to custom tools, moldable plastic offers durability, strength, and versatility in various applications. You can easily craft unique designs by following safety measures and proper molding techniques. Embrace the possibilities of working with moldable plastic and explore the innovative projects you can bring to life with this clear and versatile solution.

Frequently Asked Questions

Can moldable plastic be reused?

Yes, moldable plastic can be reused. The thermoplastic poly beads can be re-melted repeatedly, allowing you to build, reshape, and modify your creations as needed. You can find moldable plastic pellets at craft stores or online retailers.

How to achieve a smooth finish with moldable plastic?

You can use various techniques to achieve a smooth finish with moldable plastic. One option is to sand the surface after the plastic has cooled and hardened. Alternatively, you can apply a layer of paint, such as permanent markers or Polly Plastics color pellets, to create a smooth and polished look.